We understand your requirements in the area of food processing

In the food industry, display solutions are often exposed to particularly challenging environmental conditions. In addition to humidity, heat/cold, temperature fluctuations and contamination that occur during food processing, there are also very strict hygiene regulations and requirements for the safe operability of systems. Thanks to perfectly matched hardware and software components, we meet these challenges with confidence and realise products that are perfectly designed to your ideas and needs!

Let us realise your product vision!

In accordance with the NSF/ANSI 169-2016 standard, our products meet the necessary requirements for handling and processing food.

Robust components ensure maximum resistance

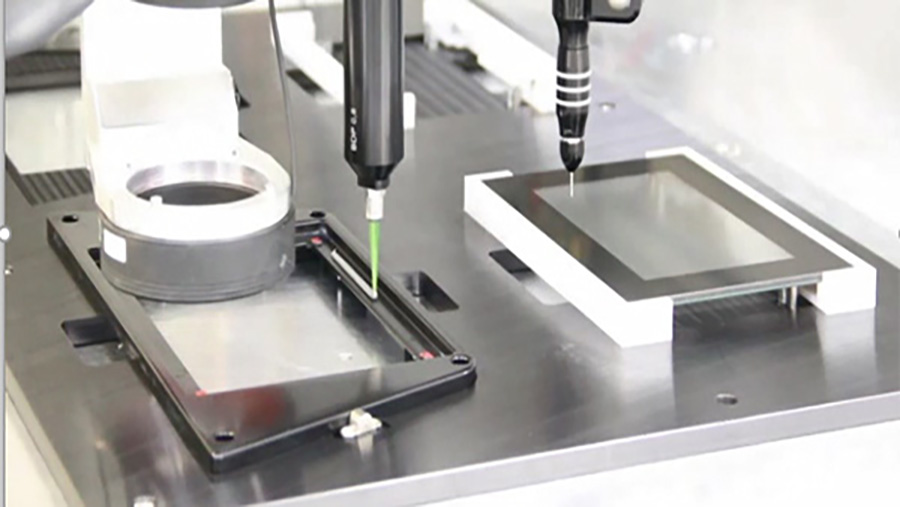

To successfully withstand the demanding environmental conditions of the food industry, the use of particularly resistant systems is crucial. We offer you a wide range of robust components, that effortlessly meet these challenges. Whether displays with extended temperature ranges, scratch-resistant cover glasses and PMMA/polycarbonate covers, IP-protected housings or special manufacturing processes, such as our bonding technologies – we offer you everything from a single source!

Highest hygiene standards for uncompromising cleanliness in food processing

Strict guidelines apply to systems which are used in food processing to ensure high hygienic standards.

In order to prevent dirt, germs or liquids from entering the housing and to enable simple, hygienic cleaning, we offer various sealing concepts. Gaps created in the production process can be closed with our gap-filling process. We are also able to realise state-of-the-art systems with the currently highest ingress protection class IPX9.

When selecting the appropriate cover glass material, we carefully take care that the surface is not attacked by contact with food or cleaning chemicals. To avoid splinters in the event of a glass breakage, plastics such as PMMA or special splinter protection films can be offered as well.

We also react flexibly to your needs when it comes to the housing: whether it is stainless steel or plastic housing or a combination of both: we realise your individual enclosure concept.

Simple, reliable & safe operation always in view

In order to avoid potential false tripping due to external influences, e.g. liquids, strong temperature fluctuations or electromagnetic interference, the most modern PCAP systems, touch controllers and extensive expertise in tuning touch settings are crucial. If required, we adapt the touch settings of your application individually and implement multitouch function, palm suppression or enable operation with gloves.

Realise your project together with us!

Packaging station

Production monitoring

Sorting plants

Filling stations

Downloads

Precise adaptation to the specific requirements of the food industry

For display systems used in food processing, products of the highest resistance, quality and reliability are required. We match all materials, electronic components and the design of the device perfectly to the conditions of the area of application - always in accordance with the latest hygiene regulations. Additional features such as RFID or proximity sensors can be integrated on request and round off our modular product portfolio perfectly.

Interested? Don't hesitate to contact us!

Do you have any questions?

Give us a call!

+49 89 56017 0*

*Our hotline is open Monday to Friday from 8 a.m. to 5 p.m. Costs according to your tariff for calls to the German landline.