Optical bonding materials

LOCA / OCR

LOCA (Liquid Optically Clear Adhesive) is a liquid, optically transparent adhesive that we cure using UV light. This highly transparent adhesive is ideal for the precise bonding of rigid components such as TFT displays, touch sensors and cover glasses.

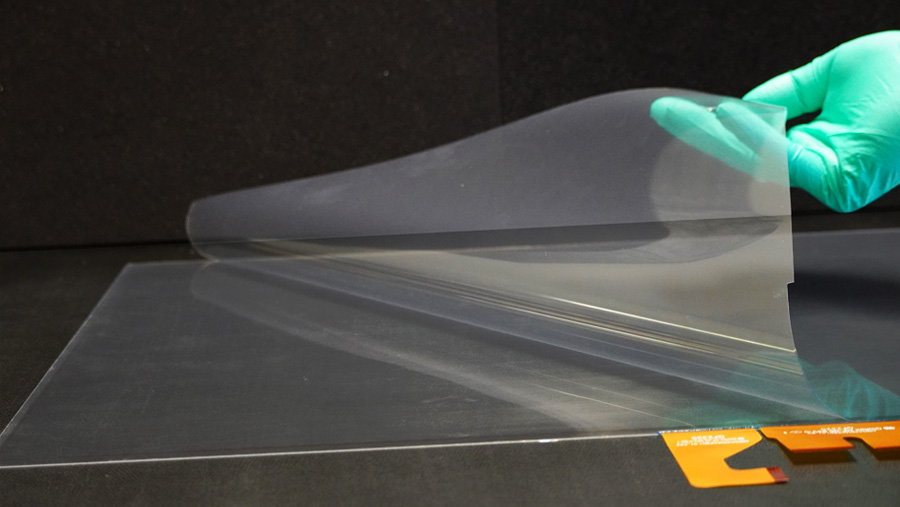

OCA

OCA (Optically Clear Adhesive) is a transparent adhesive coating that is used particularly in lamination processes. This adhesive is suitable for bonding flexible and rigid components and is often used for bonding FF sensors to cover glass.

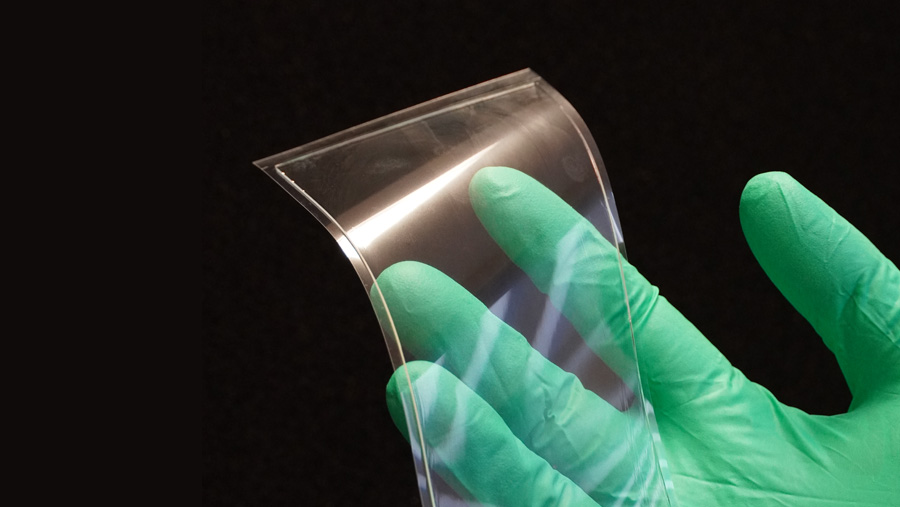

Gel

Gel is a flexible adhesive film that is ideal for the optical bonding of rigid components such as TFT displays and cover glasses. Thanks to its high flexibility, the gel adapts ideally to the surfaces and provides an even, transparent bond.

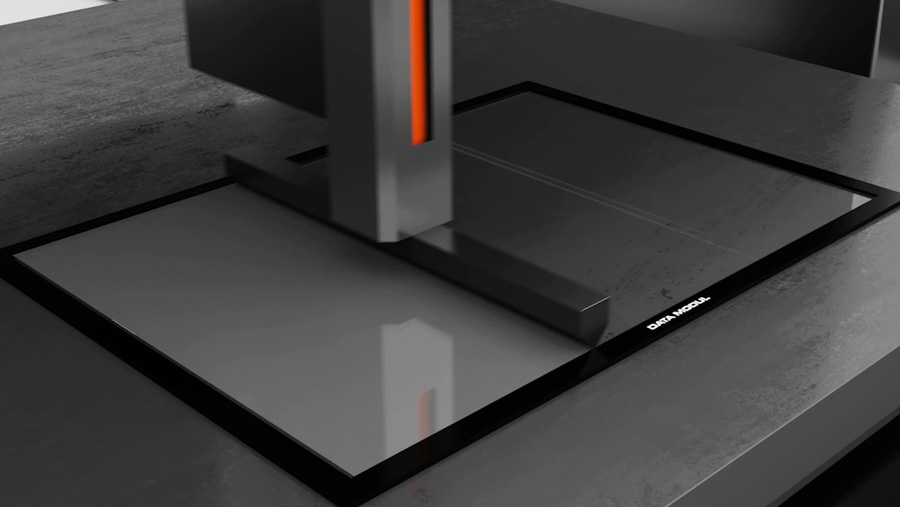

Optical bonding processes

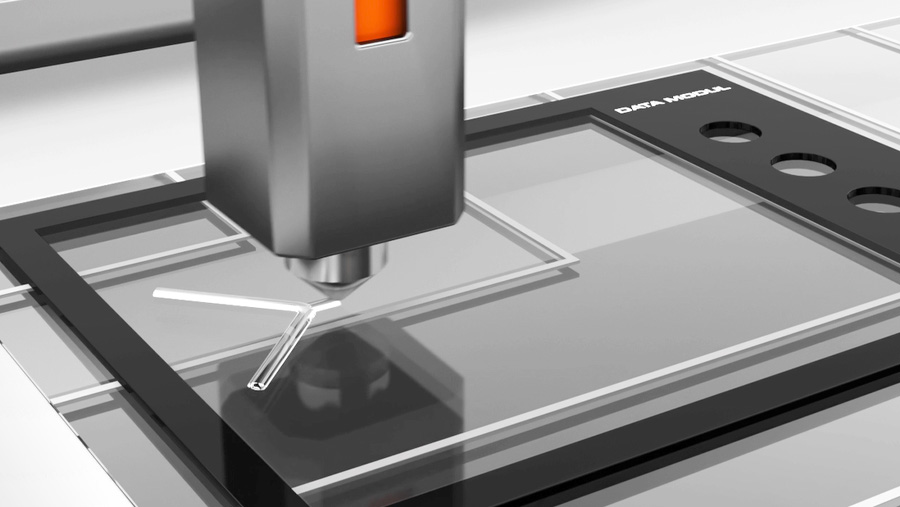

Dam & Fill

Dam & Fill is a precise process in which liquid adhesive is applied in a targeted manner to bond displays, touch and cover glasses. Curing takes place quickly and efficiently using UV light.

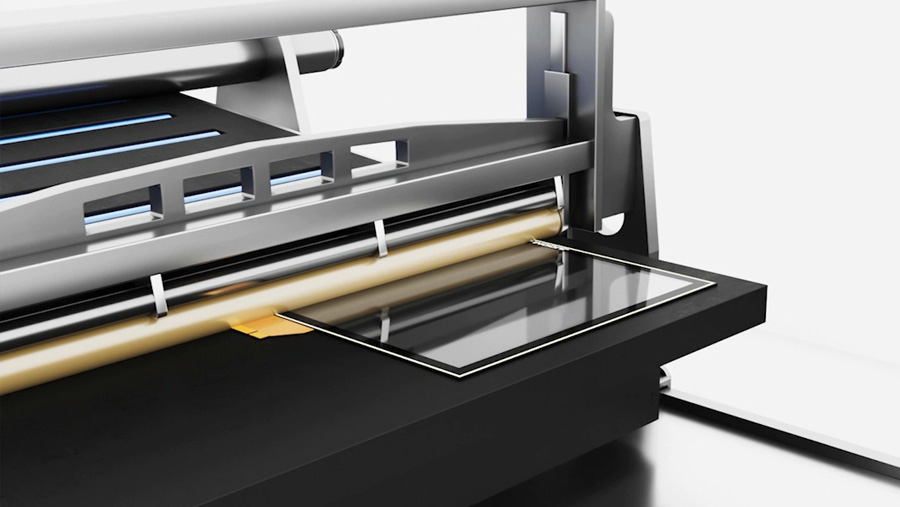

Lamination

Lamination combines flexible and rigid components using roll lamination and an autoclave process. An OCA coating ensures a homogeneous and stable optical bond.

Hybrid optical bonding

Hybrid optical bonding combines the advantages of LOCA and gel in a cost-efficient process. The slit coating process enables precise adhesive application, ideal for high-volume touch solutions.

E-field

E-field is an innovative process for cost-effective touch solutions on a large scale. It uses an electric field to control the joining process of cover glass and displays.