Structural bonding materials

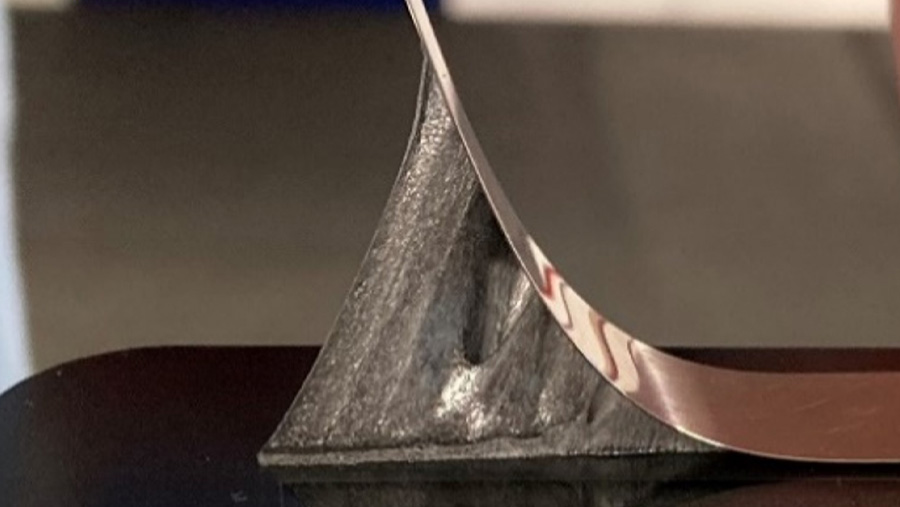

PSA (pressure-sensitive adhesive)

PSA is often used in the form of double-sided adhesive tape. The type of PSA we use is characterised by its high flexibility and is therefore ideal for bonding heterogeneous parts. This adhesive is particularly popular for structural bonding, such as the joining of TFTs and cover glass (air bonding).

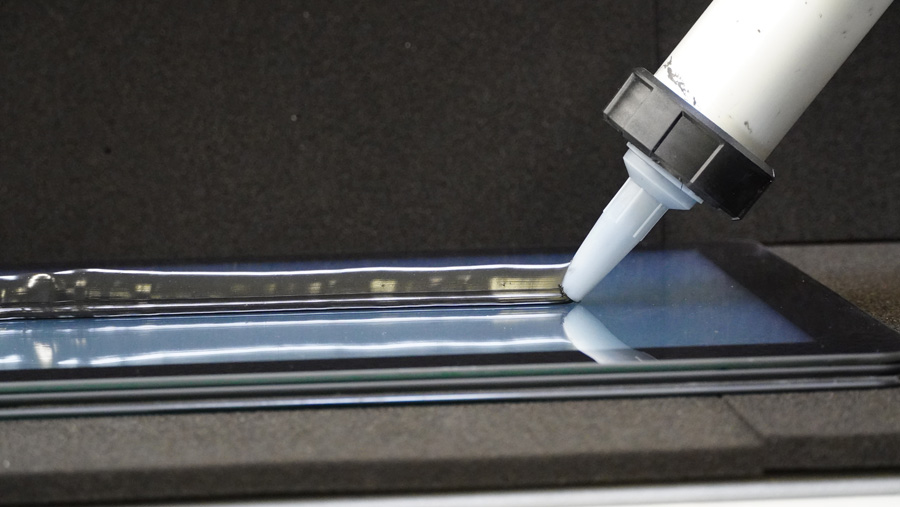

MS polymer

MS polymer is a special structural adhesive based on polyurethanes with silane functionalisation. These modified silanes offer greater elasticity, which means that long-term stable and dense adhesive bonds can be realised. The adhesive is dispensed as a liquid and can be processed both manually and automatically.

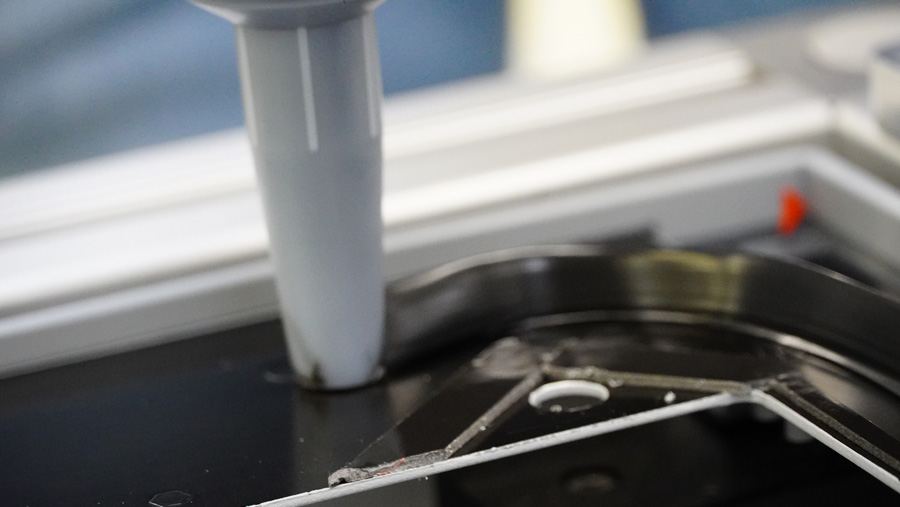

Hot melt

Hot melt is a structural adhesive based on a thermoplastic. It is dispensed in a hot, liquid state and processed immediately, which enables rapid curing and therefore ensures short cycle times.

Structural bonding processes

Plasma

The plasma process is used to clean and activate plastic surfaces. The use of plasma prepares the surface so that the adhesion of the adhesive is improved.

Manual / Air bonding

Air bonding describes the bonding of display and cover glass, often using double-sided adhesive tape. The process can be manual or automated, whereby the adhesive is usually dispensed automatically, while the bonding is carried out manually or semi-automatically.

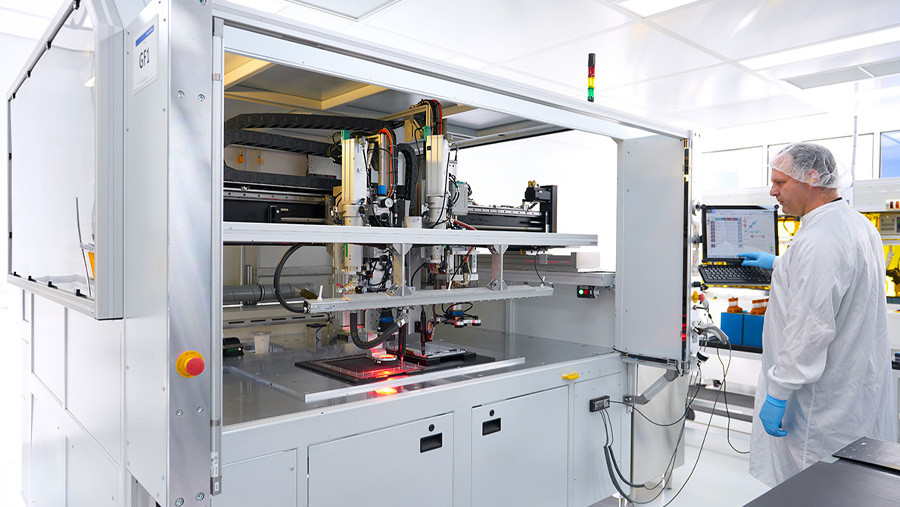

(Semi-)automatic bonding

(Semi-)automatic bonding includes the automatic dosing of structural adhesives and the option of carrying out the joining process partially or fully automatically

Hybrid Structural Bonding

Hybrid structural bonding combines several structural adhesives to combine the advantages of fast curing and high long-term stability.